Capacity - Up to 500 Ton

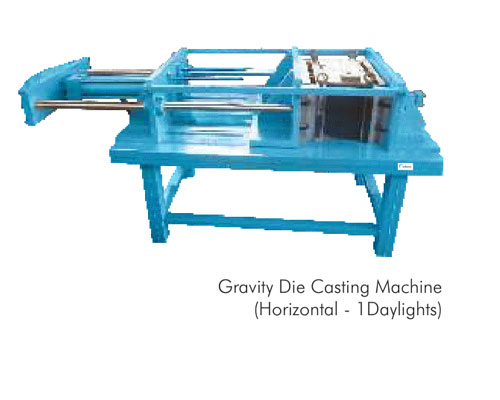

Gravity Die Casting Machines

Gravity dies casting is a metal casting process that uses the force of gravity to fill a mold with molten metal. In this process, the mold, also known as a die, is positioned vertically / Horizontally and the molten metal is poured into the mold through a pouring cup or sprue. The metal then flows into the mold cavities under the influence of gravity, solidifying it into the desired shape.

Gravity die casting is used to produce complex and accurate parts with good surface finish and dimensional accuracy, while minimizing blow holes and porosity. At Achieve Hydraulics & Pneumatics, this process is commonly used to manufacture aluminum and zinc components, and it can also be applied to other metals such as lead, magnesium, and copper alloys. The process is well suited for high-volume production and is widely used in the manufacture of automotive parts, electrical components, and a variety of other industrial applications.

Key Features

-

-

Pressure - Up to 350 bar

-

Tilting - Up to 180

-

Fabricated, ultrasonically tested steel construction frame.

-

Accurate slide guiding arrangement

-

Bottom cushioning arrangement

-

Stroke Limiter and damping device

-

Efficient and low noise hydraulic drive systems accurate slide parallelism arrangement

-

Operator safety system

-

Cylinder fast approach, slow pressing and fast return speed

Hydraulic Power Pack - 280 bar (Vikram Sarabhai Space Center)

Gravity Die Casting Machine (Tilting 90 )

Gravity Die Casting Machine (Vertical)

Gravity Die Casting Machine