Hydraulic vs Pneumatic Cylinders – Which One to Choose?

Introduction

When it comes to choosing between hydraulic and pneumatic cylinders, understanding the core differences is critical. These two types of actuators serve similar functions—providing linear motion—but the power source and applications differ significantly. In this blog, we’ll compare both types, explain their advantages and limitations, and help you make an informed decision for your project.

- Operate at high pressure (up to 5000 psi or more)

- Provide high force output

- Robust and durable

- Suitable for heavy machinery, construction, and industrial uses

- Operate at low to moderate pressure (80–100 psi)

- Fast response and high-speed cycling

- Cleaner operation (no fluid leaks)

- Commonly used in automated systems, packaging, and robotics

- You need to lift heavy loads

- Your operation requires continuous force

- Your environment tolerates fluid leakage

- Applications include: construction equipment, injection molding machines, press systems

- You need fast, repetitive motion

- You operate in a cleanroom or food-grade environment

- Lower force is acceptable

- Applications include: packaging lines, robotic arms, assembly automation

- High power-to-size ratio

- Handles extreme loads

- Better position control in some cases

- Higher maintenance (due to fluid leaks)

- Bulkier system with fluid tanks and pumps

- Risk of contamination

- Lightweight and compact

- Fast and clean operation

- Lower cost and easy to maintain

- Limited force output

- Air can compress, affecting precision

- Noisy in some systems

- Mining

- Oil & Gas

- Heavy Equipment

- Marine

- Food & Beverage

- Electronics

- Textile

- Automotive assembly

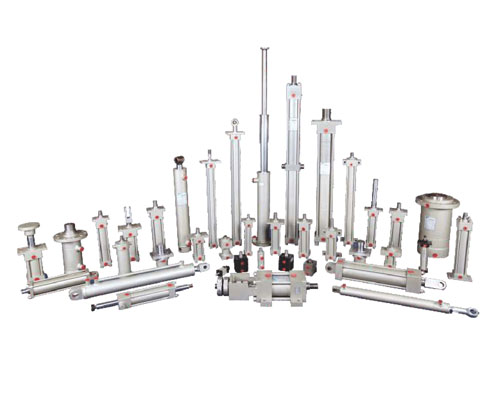

What Are Hydraulic Cylinders?

Overview

The Hydraulic cylinders use pressurized fluid (usually oil) to generate force and motion. These are best suited for heavy-duty applications where high force is needed.

Key Features of Hydraulic Cylinders

What Are Pneumatic Cylinders?

Overview

The Pneumatic cylinders use compressed air to create linear motion. They are ideal for light to medium-duty applications that require speed and simplicity.

Key Features of Pneumatic Cylinders

Hydraulic vs Pneumatic Cylinders – Comparison Table

| Feature | Hydraulic Cylinder | Pneumatic Cylinder |

|---|---|---|

| Power Source | Pressurized fluid (oil) | Compressed air |

| Pressure Range | 1000 – 5000+ psi | 60 – 150 psi |

| Force Output | Very High | Moderate |

| Speed | Slower | Faster |

| Cleanliness | Requires fluid management | Cleaner (no oil) |

| Application | Heavy-duty machinery | Light-duty automation |

| Maintenance | Higher | Lower |

| Cost | Higher initial and running cost | More cost-effective |

Which One Should You Choose?

Choose Hydraulic Cylinders If:

Choose Pneumatic Cylinders If:

Pros and Cons

Hydraulic Cylinder Pros:

Hydraulic Cylinder Cons:

Pneumatic Cylinder Pros:

Pneumatic Cylinder Cons:

Real-World Use Cases

Industries Using Hydraulic Cylinders

Industries Using Pneumatic Cylinders

Enquiry – Need Help Choosing the Right Cylinder?

Still unsure whether to choose hydraulic or pneumatic for your application? Our experts are here to help.

📩 Contact us today for a free consultation and find the best actuator system for your needs. 🔗 Get a Free Quote

Conclusion

Choosing between hydraulic and pneumatic cylinders depends entirely on your application, budget, and force requirements. Hydraulic cylinders offer power and durability; pneumatic cylinders deliver speed and cleanliness. Evaluate your project’s needs carefully, and if you need expert advice, don't hesitate to reach out to us.